(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

68.800 Stock items for Same Day Shipping

68.800 Item Stok untuk Pengiriman di Hari yang Sama

Search by Category / Brand

Pencarian dengan

Kategori / Merek

Search by Category Pencarian dengan Kategori

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

- Komponen Mekanis

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Sekrup, Baut, Washer, Nut

- Material

- Komponen Kabel

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Elektrikal & Kontrol

- Peralatan Pemotong

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Peralatan Produksi

- Penanganan Material & Penyimpanan

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Perlengkapan Keamanan & Umum

- Perlengkapan Sanitasi & Lab

- Komponen Press Die

- Komponen Plastik Mold

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Komponen Injeksi Moulding

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Brand Pencarian dengan Merek

This translation is a Google translation Terjemahan ini adalah terjemahan Google

- Penghentian penjualan kategori produk pneumatik Seri Ekonomi (E-series). Info Detail

Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

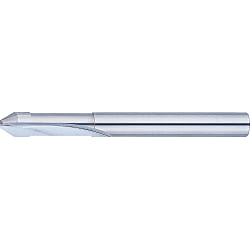

Carbide Straight Edge Corner Angle End Mill, 2-Flute / Neck Relief Type (Part Numbers)

[Features]

·Corner angle shape neck relief type that achieves efficient processing for deep work

Part Number

Configured Part Number is shown.

| Part Number |

|---|

| BSZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| BSZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| BSZCAEM16-[10.01-16/0.01]-[5-85/1]-[0-59/1]-[0.1-7.9/0.01]-[3-43/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| LS-BSZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| LS-BSZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| LS-SZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| LS-SZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM4-[3.01-4/0.01]-[5-85/1]-[0-59/1]-[0.1-1.9/0.01]-[3-10/0.5]-[5-12/0.5]-[F,T] |

| SZCAEM6-[3.01-6/0.01]-[5-85/1]-[0-59/1]-[0.1-2.9/0.01]-[3-19/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM8-[4.01-8/0.01]-[5-85/1]-[0-59/1]-[0.1-3.9/0.01]-[3-23/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM10-[6.01-10/0.01]-[5-85/1]-[0-59/1]-[0.1-4.9/0.01]-[3-30/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM12-[8.01-12/0.01]-[5-85/1]-[0-59/1]-[0.1-5.9/0.01]-[3-31/0.5]-[5-20/0.5]-[F,T] |

| SZCAEM16-[10.01-16/0.01]-[5-85/1]-[0-59/1]-[0.1-7.9/0.01]-[3-43/0.5]-[5-20/0.5]-[F,T] |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Shank Diameter d (mm) | Overall Length L (mm) | Processing Applications | Corner Angle (Single Angle)(θ) (°) | Corner Angle (Single Angle)(θ) (′) | Angular Width (D1) (mm) | Bottom Blade Shape | Flute Diameter (D) (mm) | Flute Length (ℓ) (mm) | Neck Length (ℓ1) (mm) | Use | Below Neck Length Specified Range ℓ2 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 10 Day(s) or more | 4 | 50 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 1.9 | F (Flat) / T (Center Dented) | 3.01 ~ 4 | 3 ~ 10 | 5 ~ 12 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 15 | ||

- | 1 Piece(s) | 10 Day(s) or more | 6 | 60 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 2.9 | F (Flat) / T (Center Dented) | 3.01 ~ 6 | 3 ~ 19 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 24 | ||

- | 1 Piece(s) | 10 Day(s) or more | 8 | 60 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 3.9 | F (Flat) / T (Center Dented) | 4.01 ~ 8 | 3 ~ 23 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 28 | ||

- | 1 Piece(s) | 10 Day(s) or more | 10 | 80 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 4.9 | F (Flat) / T (Center Dented) | 6.01 ~ 10 | 3 ~ 30 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 35 | ||

- | 1 Piece(s) | 10 Day(s) or more | 12 | 80 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 5.9 | F (Flat) / T (Center Dented) | 8.01 ~ 12 | 3 ~ 31 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 36 | ||

- | 1 Piece(s) | 10 Day(s) or more | 16 | 100 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 7.9 | F (Flat) / T (Center Dented) | 10.01 ~ 16 | 3 ~ 43 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 48 | ||

- | 1 Piece(s) | 10 Day(s) or more | 4 | 80 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 1.9 | F (Flat) / T (Center Dented) | 3.01 ~ 4 | 3 ~ 10 | 5 ~ 12 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 15 | ||

- | 1 Piece(s) | 10 Day(s) or more | 6 | 90 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 2.9 | F (Flat) / T (Center Dented) | 3.01 ~ 6 | 3 ~ 19 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 24 | ||

- | 1 Piece(s) | 10 Day(s) or more | 8 | 90 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 3.9 | F (Flat) / T (Center Dented) | 4.01 ~ 8 | 3 ~ 23 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 28 | ||

- | 1 Piece(s) | 10 Day(s) or more | 10 | 120 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 4.9 | F (Flat) / T (Center Dented) | 6.01 ~ 10 | 3 ~ 30 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 35 | ||

- | 1 Piece(s) | 10 Day(s) or more | 12 | 120 | Boss Hole Drilling | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 5.9 | F (Flat) / T (Center Dented) | 8.01 ~ 12 | 3 ~ 31 | 5 ~ 20 | For Boss Hole Drilling | ℓ + ℓ1 ≤ 36 | ||

- | 1 Piece(s) | 10 Day(s) or more | 4 | 80 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 1.9 | F (Flat) / T (Center Dented) | 3.01 ~ 4 | 3 ~ 10 | 5 ~ 12 | For Radial Groove Milling | ℓ + ℓ1 ≤ 15 | ||

- | 1 Piece(s) | 10 Day(s) or more | 6 | 90 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 2.9 | F (Flat) / T (Center Dented) | 3.01 ~ 6 | 3 ~ 19 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 24 | ||

- | 1 Piece(s) | 10 Day(s) or more | 8 | 90 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 3.9 | F (Flat) / T (Center Dented) | 4.01 ~ 8 | 3 ~ 23 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 28 | ||

- | 1 Piece(s) | 10 Day(s) or more | 10 | 120 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 4.9 | F (Flat) / T (Center Dented) | 6.01 ~ 10 | 3 ~ 30 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 35 | ||

- | 1 Piece(s) | 10 Day(s) or more | 12 | 120 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 5.9 | F (Flat) / T (Center Dented) | 8.01 ~ 12 | 3 ~ 31 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 36 | ||

- | 1 Piece(s) | 10 Day(s) or more | 4 | 50 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 1.9 | F (Flat) / T (Center Dented) | 3.01 ~ 4 | 3 ~ 10 | 5 ~ 12 | For Radial Groove Milling | ℓ + ℓ1 ≤ 15 | ||

- | 1 Piece(s) | 10 Day(s) or more | 6 | 60 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 2.9 | F (Flat) / T (Center Dented) | 3.01 ~ 6 | 3 ~ 19 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 24 | ||

- | 1 Piece(s) | 10 Day(s) or more | 8 | 60 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 3.9 | F (Flat) / T (Center Dented) | 4.01 ~ 8 | 3 ~ 23 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 28 | ||

- | 1 Piece(s) | 10 Day(s) or more | 10 | 80 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 4.9 | F (Flat) / T (Center Dented) | 6.01 ~ 10 | 3 ~ 30 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 35 | ||

- | 1 Piece(s) | 10 Day(s) or more | 12 | 80 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 5.9 | F (Flat) / T (Center Dented) | 8.01 ~ 12 | 3 ~ 31 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 36 | ||

- | 1 Piece(s) | 10 Day(s) or more | 16 | 100 | Flank / Groove Processing | 5 ~ 85 | 0 ~ 59 | 0.1 ~ 7.9 | F (Flat) / T (Center Dented) | 10.01 ~ 16 | 3 ~ 43 | 5 ~ 20 | For Radial Groove Milling | ℓ + ℓ1 ≤ 48 |

Loading...

Specifications

[ ! ]Even if dimensions within the specifiable range are specified, depending on the combination of each dimension some products may be unable to be manufactured.

| Model Number | Flute Diameter D 0.01 mm Increment Designation | Corner Angle (Single Angle) θ ° - ' 1' Increment Designation | Angular Width D1 0.01 mm Increment Designation | Blade Length * ℓ 0.5 mm Increment Designation | Neck Length * ℓ1 1 mm Increment Designation | Bottom Blade Shape (Selection) | * Length Under Neck Specified Range ℓ2 | Overall Length L | ||

| Shank Diameter d | ||||||||||

| BSZCAEM | LS-BSZCAEM | |||||||||

| BSZCAEM LS-BSZCAEM (Long Shank) | 4 | 3.01 ~ 4.00 | 5° 0' ~ 85° 0' | 0.10 ≤ D1 ≤ (D - 0.2) / 2 | 3.0 ~ 10.0 | 5 ≤ ℓ1 ≤ 20 | T (Dished) F (Flat) Bottom Blade Shape >>P.608 | ℓ + ℓ1 ≤ 15 | 50 | 80 |

| 6 | 3.01 ~ 6.00 | 3.0 ~ 19.0 | ℓ + ℓ1 ≤ 24 | 60 | 90 | |||||

| 8 | 4.01 ~ 8.00 | 3.0 ~ 23.0 | ℓ + ℓ1 ≤ 28 | 60 | 90 | |||||

| 10 | 6.01 ~ 10.00 | 3.0 ~ 30.0 | ℓ + ℓ1 ≤ 35 | 80 | 120 | |||||

| 12 | 8.01 ~ 12.00 | 3.0 ~ 31.0 | ℓ + ℓ1 ≤ 36 | 80 | 120 | |||||

| 16 | 10.01 ~ 16.00 | 3.0 ~ 43.0 | ℓ + ℓ1 ≤ 48 | 100 | - | |||||

| Model Number | Flute Diameter D 0.01 mm Increment Designation | Corner Angle (Single Angle) θ ° - ' 1' Increment Designation | Angular Width D1 0.01 mm Increment Designation | Blade Length * ℓ 0.5 mm Increment Designation | Neck Length * ℓ1 1 mm Increment Designation | Bottom Blade Shape (Selection) | * Length Under Neck Specified Range ℓ2 | Overall Length L | ||

| Shank Diameter d | ||||||||||

| SZCAEM | LS-SZCAEM | |||||||||

| SZCAEM LS-SZCAEM (Long Shank) | 4 | 3.01 ~ 4.00 | 5° 0' ~ 85° 0' | 0.10 ≤ D1 ≤ (D - 0.2) / 2 | 3.0 ~ 10.0 | 5 ≤ ℓ1 ≤ 20 | T (Dished) F (Flat) Bottom Blade Shape >>P.608 | ℓ + ℓ1 ≤ 15 | 50 | 80 |

| 6 | 3.01 ~ 6.00 | 3.0 ~ 19.0 | ℓ + ℓ1 ≤ 24 | 60 | 90 | |||||

| 8 | 4.01 ~ 8.00 | 3.0 ~ 23.0 | ℓ + ℓ1 ≤ 28 | 60 | 90 | |||||

| 10 | 6.01 ~ 10.00 | 3.0 ~ 30.0 | ℓ + ℓ1 ≤ 35 | 80 | 120 | |||||

| 12 | 8.01 ~ 12.00 | 3.0 ~ 31.0 | ℓ + ℓ1 ≤ 36 | 80 | 120 | |||||

| 16 | 10.01 ~ 16.00 | 3.0 ~ 43.0 | ℓ + ℓ1 ≤ 48 | 100 | - | |||||

* The combined dimensions of the blade length (ℓ) and neck length (ℓ1) will be within the length under neck specified range.

Alterations

Basic Information

| Material | Ultrafine Particulate Carbide |

|---|

Specification/Dimensions

-

Shank Diameter d(mm)

- 4

- 6

- 8

- 10

- 12

- 16

-

Overall Length L(mm)

-

Processing Applications

- Boss Hole Drilling

- Flank / Groove Processing

-

Corner Angle (Single Angle)(θ)(°)

-

Corner Angle (Single Angle)(θ)(′)

-

Angular Width (D1)(mm)

-

Bottom Blade Shape

- F (Flat)

- T (Center Dented)

-

Flute Diameter (D)(mm)

-

Flute Length (ℓ)(mm)

-

Neck Length (ℓ1)(mm)

-

type

- BSZCAEM

- LS-BSZCAEM

- LS-SZCAEM

- SZCAEM

Days to Ship

-

- All

- 10 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Tech Support

- Factory Automation, Electronics, Tools, & MRO (Maintenance, Repair and Operations)

- Tel:021-8990-4102 / FAX:021-8990-5803

- 8:30am - 5:30pm (Monday - Friday)

- Technical Inquiry

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Kebijakan Privacy

Thank you for your cooperation.Terima kasih atas kerjasama anda.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Silahkan pergunakan Forms Permintaan.

Kebijakan Privacy