(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

68.800 Stock items for Same Day Shipping

68.800 Item Stok untuk Pengiriman di Hari yang Sama

Search by Category / Brand

Pencarian dengan

Kategori / Merek

Search by Category Pencarian dengan Kategori

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

- Komponen Mekanis

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Sekrup, Baut, Washer, Nut

- Material

- Komponen Kabel

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Elektrikal & Kontrol

- Peralatan Pemotong

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Peralatan Produksi

- Penanganan Material & Penyimpanan

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Perlengkapan Keamanan & Umum

- Perlengkapan Sanitasi & Lab

- Komponen Press Die

- Komponen Plastik Mold

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Komponen Injeksi Moulding

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Brand Pencarian dengan Merek

This translation is a Google translation Terjemahan ini adalah terjemahan Google

- Penghentian penjualan kategori produk pneumatik Seri Ekonomi (E-series). Info Detail

Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Precision Ball Screws Shaft Dia.10 Lead 2/4 Accuracy Grade C5

- Precision Ball Screws Shaft Dia.10 Lead 2/4 Accuracy Grade C5 from MISUMI.

- Precision Ball Screws have a shaft diameter of 10 mm and are available in two different lead sizes: 2mm or 4mm.

- The accuracy grade option for this product is C5.

- The overall length of the shaft screw can be customized to fit a range of configurations, from 100mm to 315mm, in 1mm increments.

- The lead twisting direction for this product is right-handed.

- The screw shaft is made of S55C while the nut is made of SCM420.

Part Number

Configured Part Number is shown.

Economy Precision Ball Screws Shaft Dia.10

- Precision Ball Screws with specified shaft diameter and available in multiple lead sizes

- High accuracy grade of C5 for enhanced precision

- Customizable shaft screw lengths within a specified range in 1mm increments

- S55C screw shaft and SCM420 nut for superior durability and wear resistance

- Suitable for high-precision positioning mechanisms in automation equipment

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview

1. This series of products is the C5 Precision Ball Screw with the shaft diameter of 10 and lead of 2/4.2. With small backlash of the nut, it has higher precision and lower noise than the rolled Ball Screw, but the motor starting torque will increase.

3. It is more suitable for positioning mechanisms in FA automation equipment.

4. The screw shaft end is machined according to standard specifications. If the shaft end requires alteration, it should be specified according to the catalog.

| Model No./Specification Example | |||||

| Model No. | Accuracy | Shaft Dia. | Lead | Total Length | |

| MISUMI Standard Product | BSS1004-300 | C5 | 10 | 4 | 300 |

| C-Value | C-BSS1004-300 | ||||

| Economy Series | C-KBS1004-300 | C5 equivalent*1 | |||

■ Lead Accuracy

■ Fluctuation Tolerances

Unit: μm

| Accuracy Class | C3 | C5 | ||

| Item | Fluctuation (300) (2) | Fluctuation (2π) (3) | Fluctuation (300) (2) | Fluctuation (2π) (3) |

| Fluctuation Tolerance | 8 | 6 | 18 | 8 |

(2) Fluctuation for an arbitrary length of 300mm within the effective thread length of the screw shaft

(3) Fluctuation for an arbitrary 1 rotation (2π rad) within the effective thread length of the screw shaft

■ Mounting Part Accuracy

Ground Ball Screw

| Model | Lead | Screw Length | (1)(2) Runout Tolerance (Max.) | (3) Runout Tolerance (Max.) | (4)(5) Perpendicularity Tolerance (Max.) | (6) Perpendicularity Tolerance (Max.) | (7) Perpendicularity Tolerance (Max.) | Axial Clearance | ||||||||||||||

| Type | Screw Shaft Outer Dia. | Min. | Max. | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | MISUMI Standard Product (BSS) | C-Value | Economy Series C-KBS | |

| C-KBS | 8 | 2 | 100 | 210 | 0.011 | 0.014 | 0.011 | 0.014 | 0.005 | 0.02 *Reference value | 0.01 | Not guaranteed | 0.012 | Not guaranteed | 0.005 or less | 0.008 or less | 0.008 or less | |||||

| 10 | 2/4 | 100 | 350 | |||||||||||||||||||

| 12 | 4/10 | 150 | 500 | |||||||||||||||||||

| 15 | 5/10/20 | 150 | 1100 | 0.012 | 0.012 | 0.011 | 0.015 | 0.015 or less | 0.015 or less | |||||||||||||

| 20 | 5/10/20 | 200 | 1500 | |||||||||||||||||||

| 25 | 5/10/25 | 300 | 1500 | 0.013 | 0.013 | 0.013 | 0.019 | |||||||||||||||

This measurement item is affected by Total Run-out (8) of the Screw Shaft, and so it must be corrected.

(3) Radial runout of drive component interface surface in relation to screw shaft support axis.

(4)・(5) Perpendicularity of shaft's bearing shoulders in relation to screw shaft support axis.

(6) Perpendicularity of ball nut mounting flange surface (datum) in relation to screw shaft axis.

(7) Radial runout of ball nut body outer circumference in relation to screw shaft axis.

Dimensional Drawing

| Type | Accuracy grade | Screw diameter | Lead | Screw shaft | Nut | ||||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | ||||

| C-KBS | C5 | 10 | 2·4 | Equivalent to S55C | High frequency quenching 58 to 62HRC | - | Equivalent to SCM420 | Carburized 58 to 62HRC | - |

| Part Number |  L L(1mm increments) | Y | Number of cycles | Basic Rated Load | Axial Clearance | Twisting Direction | Screw support unit (Sold separately) | |||||

Type Type |  Screw Shaft O.D. Screw Shaft O.D. |  Lead Lead | C (Dynamic) kN | C (Static) kN | Shape | Fixed side model | Support side model | |||||

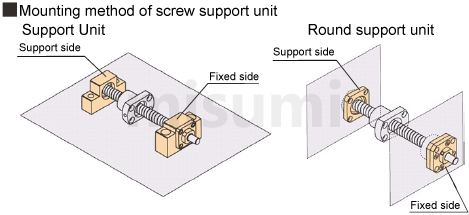

| C - KBS | 10 | 02 | 100 to 350 | L-53 | 3 laps | 1.2 | 2.1 | 0.008 or Less | Right | Square Type | C-TEK8 | C-TEF8 |

| Round type | C-TFK8 | C-TFF6 | ||||||||||

| 04 | 1.6 | 3.4 | Square Type | C-TEK8 | C-TEF8 | |||||||

| Round type | C-TFK8 | C-TFF6 | ||||||||||

| * The Y dimension must be larger than the full length of the nut | kgf=N× 0.101972 | |||||||||||

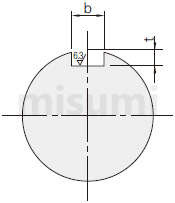

| Shaft Dia. | b | t | ||

| Reference dimension | Tolerance (N9) | Reference dimension | Tolerance | |

| 6 to 7 | 2 | -0.004 -0.029 | 1.2 | +0.1 0 |

| 8 to 10 | 3 | 1.8 | ||

| 11 to 12 | 4 | 0 -0.03 | 2.5 | |

| 13 to 17 | 5 | 3.0 | ||

| 18 to 20 | 6 | 3.5 | ||

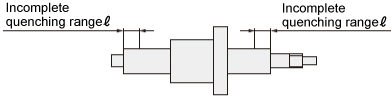

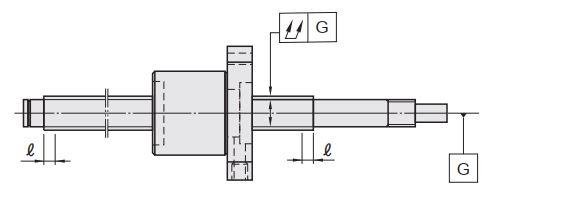

| Screw diameter | Incomplete quenching range ℓ (max) |

| φ8, φ10 | 5mm |

| φ12, φ15 | 10mm |

| φ20, φ25 | 15mm |

| Type | Screw Shaft O.D. | Runout tolerance G (Max.) | Incomplete Hardened Area (ℓ) | ||||||||||

| ~125 | 126~200 | 201~315 | 316~400 | 401~500 | 501~630 | 631~800 | 801~1000 | 1001~1250 | 1251~1600 | 1601~2000 | |||

| E-TBS | 4 | 0.060 | 0.075 | - | - | - | - | - | - | - | - | - | 5 |

| 6 | 0.075 | 0.075 | - | - | - | - | - | - | - | - | - | ||

| C-TBSE C-TBSB | 8 | 0.100 | 0.140 | 0.210 | 0.270 | - | - | - | - | - | - | - | 10 |

| 10 | - | 0.120 | 0.160 | 0.210 | 0.270 | 0.350 | - | - | - | - | - | ||

| 12 | - | 0.120 | 0.160 | 0.210 | 0.270 | 0.350 | 0.480 | - | - | - | - | ||

| 15 | - | 0.110 | 0.130 | 0.160 | 0.200 | 0.250 | 0.320 | 0.420 | 0.550 | - | - | ||

| 20 | - | 0.110 | 0.130 | 0.160 | 0.200 | 0.250 | 0.320 | 0.420 | 0.550 | 0.730 | 0.730 | 15 | |

| 25 | - | 0.110 | 0.110 | 0.130 | 0.160 | 0.190 | 0.230 | 0.300 | 0.380 | 0.500 | 0.690 | ||

| 32 | - | - | 0.110 | 0.130 | 0.160 | 0.190 | 0.230 | 0.300 | 0.380 | 0.500 | 0.690 | 20 | |

| E-KBS | 4 | 0.050 | - | - | - | - | - | - | - | - | - | - | 5 |

| 6 | 0.050 | 0.050 | - | - | - | - | - | - | - | - | - | ||

| C-KBS | 8 | 0.060 | 0.075 | 0.100 | - | - | - | - | - | - | - | - | |

| 10 | 0.055 | 0.065 | 0.080 | 0.100 | - | - | - | - | - | - | - | ||

| 12 | - | 0.065 | 0.080 | 0.100 | 0.120 | - | - | - | - | - | - | 10 | |

| 15 | - | 0.060 | 0.070 | 0.080 | 0.095 | 0.110 | 0.140 | 0.170 | 0.210 | - | - | ||

| 20 | - | 0.060 | 0.070 | 0.080 | 0.095 | 0.110 | 0.140 | 0.170 | 0.210 | 0.270 | - | 15 | |

| 25 | - | - | 0.060 | 0.070 | 0.080 | 0.090 | 0.100 | 0.130 | 0.170 | 0.210 | - | ||

| E-KLR | 4 | 0.050 | 0.050 | - | - | - | - | - | - | - | - | - | 5 |

| 8 | 0.065 | 0.075 | 0.100 | - | - | - | - | - | - | - | - | ||

| 10 | 0.065 | 0.065 | 0.080 | 0.100 | - | - | - | - | - | - | - | ||

Product Features

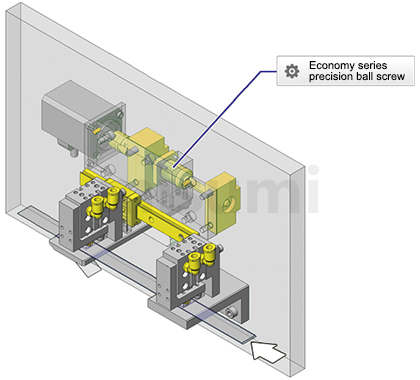

1. Drawing-based machining is no longer required, saving the time for drawing.2. When Ball Screw used in combination with Economy series support unit, it has a better effect.

3. The total length of screw shaft can be specified in 1 mm increments. With abundant shaft end specifications, it is possible to specify alterations for different applications.

Example of Use

Precautions

● The noise value of the screw after assembly is not guaranteed.

● Although lithium soap-based grease has been applied at the factory, it is required to apply new grease every 2~3 months as standard after receiving the goods, otherwise the normal use will be affected. For details, see Catalog P687.

● In operation, if there is too much noise or sharp and harsh sound, please make sure that the installation accuracy of the screw and the specifications of peripheral components such as motors and couplings are appropriate.

Do not let the nut exceed the movement range of the Ball Screw nut, or screw out of the screw shaft, otherwise the ball will fall off and the ball cycling parts will be damaged.

● Ball Screws and nuts placed with an inclination may fall due to weight. Please be careful.

● This product is a machined type, so there will be knife patterns and color difference in its appearance. Small scratches or color changes without affecting the use and main function are of a normal phenomenon. Please feel free to use.

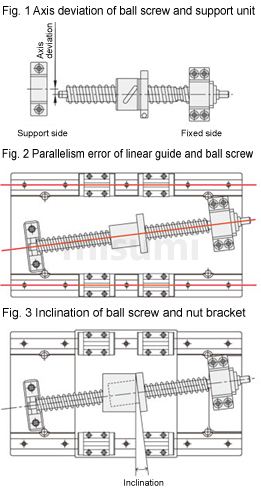

■ Precautions of the Ball Screw and peripheral parts design and assembly

The Ball Screw is a component that only bears axial load. If it is subjected to radial load or moment load, poor sliding, vibration or abnormal noise may occur, shortening its service life.

The reason that the Ball Screw bears radial load and moment load is the axis deviation and parallelism error of the surrounding parts. Therefore, it is necessary to correctly design and assemble the peripheral parts of the Ball Screw to prevent errors.

● Axis deviation of Ball Screw and support unit (Fig. 1)

- Axis deviation is the deviation of the Ball Screw fixed by the fixed side support unit and the bearing of the supporting side support unit.

-The allowable value of the axis deviation is 20μ or less (reference value)

●Parallelism between Ball Screw and linear guide (Diagram 2)

- Parallelism error refers to the inclination of the Ball Screw in the up-down or left-right direction with respect to the reference of the linear guide.

-The allowable value of inclination is below 1/2000 (Diagram 3)

●Precautions of assembly

If you notice abnormal noises during the operation of the Ball Screw or jamming during movement after assembly, please loosen the connections of the parts before proceeding. Adjust and reassemble after moving smoothly.

- Error in the left and right direction of the support unit (Fig. 1)

- Parallel error of linear guide and Ball Screw (Fig. 2)

- Fixing of workbench and nut bracket

- Fixing of Ball Screw nut and nut bracket

| ・Removal of nut is prohibited | ・No impact on the nut | ・Be careful of falling due to weight |

|  |  |

| ・Checking for reverse action | ・Pay attention to intrusion of foreign objects | ・Nut overstroke is prohibited |

|  |  |

| ||

Related Products

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| C-KBS1002-[100-350/1] |

| C-KBS1004-[100-350/1] |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Lead (mm) | Shaft Screw Overall Length L (mm) |

|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 16 Day(s) | 10 | 2 | 100 ~ 350 | ||

- | 1 Piece(s) | 16 Day(s) | - | 4 | 100 ~ 350 |

Loading...

Basic Information

| Screw Shaft O.D.(Ø) | 10 | Type | Precision | Accuracy Grade | C5 |

|---|---|---|---|---|---|

| Flange Shape Details | Round, 2 Sides Cut Flat | Fixed Side of Square Bearing Assembly (Purchase Separately) | C-TEK8 | Square Support Component Support Side (Purchase Separately) | C-TEF8 |

| Fixed Side of Round Bearing Assembly (Purchase Separately) | C-TFK8 | Support Side of Circular Support Assembly (Purchase Separately) | C-TFF6 | Motor Bracket for Panasonic 100W Servo Motor (Purchase Separately) | E-TSMP40-22 or E-TSMP40-25 |

| Motor Bracket for Panasonic 200~400W Servo Motor (Purchase Separately) | E-TSMP60-30 | Motor Bracket for Yaskawa, Mitsubishi, Delta, Inovance 100W Servo Motor (Purchase Separately) | E-TSMA40-22 or E-TSMA40-25 | Motor Bracket for Yaskawa, Mitsubishi, Delta, Inovance 200~400W Servo Motor (Purchase Separately) | E-TSMA60-30 |

| Motor Bracket for 42 Series Stepper Motor (Purchase Separately) | E-TBMD42-22 | Motor Bracket for 57 Series Stepping Motor (Purchase Separately) | E-TBMD57-30 |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is the operating temperature limit for the ball screw?

- Answer: The operating temperature limit for the ball screw is 80°. Exceeding this limit will cause damage to the circulating parts and seals, as well as the deformation of the screw shaft and nut, affecting the life. Grease has a good effect of reducing the temperature, so regular maintenance such as grease injection to the ball screw will improve the service life of the screw.

- Question: How to do if there is abnormal noise heard in use?

- Answer: MISUMI does not guarantee there is no abnormal noise during use. If abnormal noise occurs, please check the installation accuracy and the correct selection of surrounding parts. Please loosen the parts before re-adjustment. Please refer to “Precautions” for details.

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Kebijakan Privacy

Thank you for your cooperation.Terima kasih atas kerjasama anda.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Silahkan pergunakan Forms Permintaan.

Kebijakan Privacy