(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

68.800 Stock items for Same Day Shipping

68.800 Item Stok untuk Pengiriman di Hari yang Sama

Search by Category / Brand

Pencarian dengan

Kategori / Merek

Search by Category Pencarian dengan Kategori

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

- Komponen Mekanis

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Sekrup, Baut, Washer, Nut

- Material

- Komponen Kabel

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Elektrikal & Kontrol

- Peralatan Pemotong

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Peralatan Produksi

- Penanganan Material & Penyimpanan

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Perlengkapan Keamanan & Umum

- Perlengkapan Sanitasi & Lab

- Komponen Press Die

- Komponen Plastik Mold

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Komponen Injeksi Moulding

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Brand Pencarian dengan Merek

This translation is a Google translation Terjemahan ini adalah terjemahan Google

- Penghentian penjualan kategori produk pneumatik Seri Ekonomi (E-series). Info Detail

Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Miniature Linear Guides Standard (E-SMLGB20)

- Volume Discount

Miniature Linear Guides Standard

These linear guides or linear slides are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Rail Length Minimum/Maximum (mm.): 170 and 345

● Assembly Height (mm.): 8, 10, 13 and 16

● Rail Type : Standard Rail

● Option: Set (Rail + Block) / Block only

● Material: Carbon Steel and Stainless Steel

[Application]

It is used in a variety of machines such as CNC machines, 3D printers, measuring instruments, and so on.

Part Number

Configured Part Number is shown.

E-SMLGB20

Economy Miniature Linear Guide

- Customizable Rail Length For Versatile Applications

- Smooth And Precise Linear Motion

- Suitable For High Precision Equipment

- Available In Carbon Steel And Stainless Steel

- Cost-Effective Solution Without Compromising Performance

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Linear guide rails are used to support and guide moving parts, allowing them to move in a reciprocating linear motion along a specified direction. They are mainly used in mechanical structures that require high precision. The moving and fixed components of the linear guide rail do not use an intermediate medium, but instead employ rolling steel balls.

| Similar MISUMI Product SSEB10-115 | Economy Series E-GMLG9-115 | |

| Material | Stainless Steel | Carbon Steel |

| Hardness | 56HRC up | 58HRC up |

| Basic Rated Load C (Dynamic) (kN) | 1.5 | 1.86 |

| Basic Rated Load Co (Static) (kN) | 2.5 | 2.55 |

| Static Allowable Moment MA/MB (N・m) | 5.1 | 7.35 |

| Static Allowable Moment MC (N・m) | 10.2 | 11.76 |

| Height H Tolerance Difference (μm) | ±20 | ±20 |

| Height H Pair Variation Difference (μm) | 15 | 40 |

| Width N Tolerance Difference (μm) | ±25 | ±25 |

| Width N Pair Variation Difference (μm) | 20 | 40 |

| Running Parallelism Guarantee (μm)* | 7 | 15 |

| Preload Management | Y | N |

| Model No. Selection Reference | Height H Reference | Rail Width WR Reference |

| RoHS10 | Compliant | Compliant |

| Type |  Material Material |  Rail Surface Treatment Rail Surface Treatment |  Hardness Hardness | |

| Guide Rail | Block | |||

| C-MLG | Bearing Steel | Stainless Steel | - | 58-62HRC |

| E-GMLG | Vacuum evaporated chrome plating | |||

| E-SMLG | Stainless Steel | - | 55-58HRC | |

| C-MLGB | - | Stainless Steel | - | - |

■Component Kit

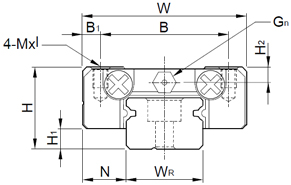

| Part Number |  L (Specified Length) L (Specified Length) | Component Dimension (mm) | Block Dimension (mm) | Guide Rail Dimension (mm) | ||||||||||||||||

Type Type |  Nominal NominalWR | H | H1 | N | W | B | B1 | C | L1 | L2 | Gn | Mxℓ | H2 | WR | Hr | D | h | d | P | |

| Normal Clearance Type | ||||||||||||||||||||

| E-GMLG (Rail:Bearing Steel) E-SMLG (Rail:Stainless Steel) | 7 | 25~900 | 8 | 1.5 | 5 | 17 | 12 | 2.5 | 8 | 13.5 | 22.65 | Φ1.2 | M2×2.5 | 1.5 | 7 | 4.8 | 4.2 | 2.3 | 2.4 | 15 |

| 9 | 35~900 | 10 | 2 | 5.5 | 20 | 15 | 2.5 | 10 | 18.9 | 29.60 | Φ1.4 | M3×3 | 1.8 | 9 | 6.5 | 6 | 3.5 | 3.5 | 20 | |

| 12 | 45~900 | 13 | 3 | 7.5 | 27 | 20 | 3.5 | 15 | 20.7 | 35.75 | Φ2 | M3×3.5 | 2.5 | 12 | 8 | 6 | 4.5 | 3.5 | 25 | |

| 15 | 70~900 | 16 | 4 | 8.5 | 32 | 25 | 3.5 | 20 | 26.7 | 43.60 | M3 | M3×4 | 3 | 15 | 10 | 6 | 4.5 | 3.5 | 40 | |

■Single Block

| Part Number | Block Dimension (mm) | |||||||||

Type Type |  Nominal Nominal | W | B | B1 | L1 | L2 | C | M×ℓ | H2 | Gn |

| C-MLGB | 7 | 17 | 12 | 2.5 | 12.5 | 25.34 | 8 | M2×2.5 | 1.5 | Φ1.2 |

| 9 | 20 | 15 | 17.5 | 28.98 | 10 | M3×3 | 1.8 | Φ1.4 | ||

| 12 | 27 | 20 | 3.5 | 20.1 | 33.9 | 15 | M3×3.5 | 2.5 | Φ2 | |

| 15 | 32 | 25 | 25.1 | 41.5 | 20 | M3×4 | 3 | M3 | ||

The dimensional tolerance for length L is ±1mm.

The dimensional tolerance for length L is ±1mm. The dimensional tolerance for end distance E is ±0.5mm.

The dimensional tolerance for end distance E is ±0.5mm.■ Allowable Load

| Nominal | Basic Rated Load | Static Allowable Moment | Mass | |||

| C (Dynamic) kN | Co (Static) kN | MA・MB N.m | MC N.m | Blcok kg | Rail kg/m | |

| 7 | 0.98 | 1.24 | 2.84 | 4.7 | 0.01 | 0.22 |

| 9 | 1.86 | 2.55 | 7.35 | 11.76 | 0.016 | 0.38 |

| 12 | 2.84 | 3.92 | 13.72 | 25.48 | 0.034 | 0.65 |

| 15 | 4.61 | 5.59 | 21.56 | 45.08 | 0.059 | 1.06 |

■ Detailed dimension of L dimension specified type

Dimension L specified type cuts both ends of the rail equally. Refer to the table below for the number of mounting holes (M) of the rail at this time.

In addition, Dimension E's calculation formula is as follows

"E" calculation formula

Economy series Miniature Linear Guide - Standard Guide Type -

| H (Nominal) | 8 (7) | 10 (9) | 13 (12) | 16 (15) | Number of mounting holes M |

| L | 25~35 | 35~47 | 45~57 | 70~87 | 2 |

| 36~50 | 48~67 | 58~82 | 88~127 | 3 | |

| 51~65 | 68~87 | 83~107 | 128~167 | 4 | |

| 66~80 | 88~107 | 108~132 | 168~207 | 5 | |

| 81~95 | 108~127 | 133~157 | 208~247 | 6 | |

| 96~110 | 128~147 | 158~182 | 248~287 | 7 | |

| 111~125 | 148~167 | 183~207 | 288~327 | 8 | |

| 126~140 | 168~187 | 208~232 | 328~367 | 9 | |

| 141~155 | 188~207 | 233~257 | 368~407 | 10 | |

| 156~170 | 208~227 | 258~282 | 408~447 | 11 | |

| 171~185 | 228~247 | 283~307 | 448~487 | 12 | |

| 186~200 | 248~267 | 308~332 | 488~527 | 13 | |

| 201~215 | 268~287 | 333~357 | 528~567 | 14 | |

| 216~230 | 288~307 | 358~382 | 568~607 | 15 | |

| 231~245 | 308~327 | 383~407 | 608~647 | 16 | |

| 246~260 | 328~347 | 408~432 | 648~687 | 17 | |

| 261~275 | 348~367 | 433~457 | 688~727 | 18 | |

| 276~290 | 368~387 | 458~482 | 728~767 | 19 | |

| 291~305 | 388~407 | 483~507 | 768~807 | 20 | |

| 306~320 | 408~427 | 508~532 | 808~847 | 21 | |

| 321~335 | 428~447 | 533~557 | 848~887 | 22 | |

| 336~350 | 448~467 | 558~582 | 888~900 | 23 | |

| 351~365 | 468~487 | 583~607 | - | 24 | |

| 366~380 | 488~507 | 608~632 | 25 | ||

| 381~395 | 508~527 | 633~657 | 26 | ||

| 396~410 | 528~547 | 658~682 | 27 | ||

| 411~425 | 548~567 | 683~707 | 28 | ||

| 426~440 | 568~587 | 708~732 | 29 | ||

| 441~455 | 588~607 | 733~757 | 30 | ||

| 456~470 | 608~627 | 758~782 | 31 | ||

| 471~485 | 628~647 | 783~807 | 32 | ||

| 486~500 | 648~667 | 808~832 | 33 | ||

| 501~515 | 668~687 | 833~857 | 34 | ||

| 516~530 | 688~707 | 858~882 | 35 | ||

| 531~545 | 708~727 | 883~900 | 36 | ||

| 546~560 | 728~747 | - | 37 | ||

| 561~575 | 748~767 | 38 | |||

| 576~590 | 768~787 | 39 | |||

| 591~605 | 788~807 | 40 | |||

| 606~620 | 808~827 | 41 | |||

| 621~635 | 828~847 | 42 | |||

| 636~650 | 848~867 | 43 | |||

| 651~665 | 868~887 | 44 | |||

| 666~680 | 888~900 | 45 | |||

| 681~695 | - | 46 | |||

| 696~710 | 47 | ||||

| 711~725 | 48 | ||||

| 726~740 | 49 | ||||

| 741~755 | 50 | ||||

| 756~770 | 51 | ||||

| 771~785 | 52 | ||||

| 786~800 | 53 | ||||

| 801~815 | 54 | ||||

| 816~830 | 55 | ||||

| 831~845 | 56 | ||||

| 846~860 | 57 | ||||

| 861~875 | 58 | ||||

| 876~890 | 59 | ||||

| 891~900 | 60 | ||||

| P | 15 | 20 | 25 | 40 |

| Alterations |  Code Code | Spec. | ||||||||

Change to Tapped Holes | MC | Ordering code: MC Change counterbored holes for fixing a guide to tapped holes.

| ||||||||

| 2-Block Specifications | B2 | 1 block added to 1-block product to ship as 2 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

| 3-Block Specifications | B3 | 2 blocks added to 1-block product to ship as 3 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

| 4-Block Specifications | B4 | 3 blocks added to 1-block product to ship as 4 block item. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package. | ||||||||

| Preload adjustment | ZF | Change Z0: zero preload to ZF: Normal clearance Z1: Light preload Z2: Medium preload | ||||||||

| Z1 | ||||||||||

| Z2 | ||||||||||

| Rail End Cut | Left End Cut ES | Specify the edge distance in 0.5 mm increments. When the specified edge distance exceeds or is close to the hole spacing, cutting may result in hole breakage. EB + ES = 2E. In cases where cutting is not feasible, distribute the dimensions evenly according to the standards. EB + ES = 2E. In cases where cutting is not feasible, distribute the dimensions evenly according to the standards. | ||||||||

| Right End Cut EB |

| Dimensional Precision Type | Precision Standard | Misumi |

| Miniature | Height H Tolerance | ±40 |

| Height H Pair Variation | 40 | |

| Width N Tolerance | ±40 | |

| Width N Pair Variation | 40 |

| Rail Length (mm) | Accuracy grade (μm) |

| Less than 50 | 12 |

| 50-80 | 13 |

| 80-125 | 15 |

| 125-200 | 15 |

| 200-250 | 16 |

| 250-315 | 17 |

| 315-400 | 18 |

| 400-500 | 19 |

| 500-630 | 20 |

| 630-800 | 22 |

| 800-900 | 23 |

[Running Parallelism]

The values in the table are measured after the slide rail is fixed on the base.

When moving the slider within the entire length of the slide rail, measure the change of the upper surface C of the slider relative to the bottom surface A of the slide rail, and the change of the reference surface D of the slider relative to the reference surface B of the slide rail.

When moving the sliding block within the entire length of the slide rail, measure the change of the upper surface C of the slider relative to the bottom surface A of the slide rail, and the change of the reference surface D of the slider relative to the reference surface B of the slide rail.

Feature 2: The slide rail and the slider are in contact with each other through the rolling ball, so the shaking is small, and it is suitable for equipment with precision requirements.

Feature 3: Due to a point-to-surface contact, the frictional resistance is small, and it can perform subtle movements to achieve high precision positioning of the device.

Feature 4: It has a large allowable load because the force on the rotating surface is dispersed due to the rolling groove of the ball.

Feature 5: It is suitable for high-speed motion because it is not easy to produce friction heat when operating and not easily deformed by heat.

② Keep the flatness of the workpiece mounting surface at about 5μ, otherwise the slider will be slightly deformed

③ Whether the error values of guide parallelism and fitting height are within the allowable installation values

④ Use the standard installation method

Click

here for the detailed installation method

here for the detailed installation methodMaintenance (supply of grease)

Grease forms an oil film on the surface of the linear guide ball and rolling surface to effectively reduce friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the

service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be used directly.

Miniature: Lithium Soap based Grease

Recommended grease filling interval: Usually every 3 months

Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty.

① MISUMI's linear guide is installed with a retainer. Although the ball is not easy to fall off when the slide block is removed, the ball may fall off if the slider is removed from the rail at high speed, or tilted into the slide rail. Please disassemble the slider with care.

② Be sure to avoid colliding the ball back groove cover, otherwise it will affect the ball cycling, resulting in poor sliding.

③ Economy series Miniature linear guide rail adopts bearing steel. If you have anti-rust requirements, please choose the Low Temp. Black Chrome Plating Surface Treatment or Stainless Steel SUS440C products.

■ About maintenance (supply of grease)

① Grease forms an oil film on the surface of the linear guide ball and rail surface to effectively reduce friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be used directly.

Miniature Linear Guide: Lithium Soap-based Grease (MULTEMP Grease PS2)

Medium· and Heavy Duty Linear Guide: Lithium Soap-based Grease (Showa Shell Petroleum Albania Grease S2)

② Recommended Grease Injection Interval:

Usually every 6 months.

For longer moving distance, 3 months, or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

*The above is the grease injection interval under the moving distance standard. Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty.

Feature 1: suitable for medium frequency driving and positioning.

Feature 2: transfer the light workpiece on the worktable according to 4 times the distance of the cylinder stroke.

For details, click

here

here| Medical | Smart phone | |

|  | |

| Robotics | Electronic & Electrical Appliances | |

|  |

| Miniature linear guide rail | Medium Load linear guide | Heavy Load linear guide | ||

|  |  | ||

| Typical model: SSEBZ10-55 | Typical model: SVR24-280 | Typical model: SXR24-280 |

here

herePart Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| E-SMLGB20 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Rail Length L | Block Type (mm) | Assembly Height H | Nominal Part Number | Rail Type | Set / Single Item | Preload (N・m) | Accuracy Standards (N・m) | Material | No. of Blocks (mm) | Lubrication Type (mm) | Lubrication Type | L Dimension Type | Applicable Linear Guide | Rail Width WR (mm) | Block Material (Surface Treatment) | Rail Material (Surface Treatment) | Rail Surface Treatment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

297,297 IDR | 1 Piece(s) | 17 Day(s) | - | - | - | - | - | - | - | - | - | - | - | Lubrication Applied | - | - | - | - | - | - | - |

Loading...

Basic Information

| Ball Arrangement | Miniature Type | Retainer | N/A | Rolling Element | Ball |

|---|

Please check the type/dimensions/specifications of the part E-SMLGB20 in the Miniature Linear Guides Standard series.

Specification/Dimensions

-

Rail Length L

-

Block Type(mm)

- Standard

- Standard

-

Assembly Height H

-

Nominal Part Number

-

Rail Type

-

Standard Rail

Standard Rail

-

-

Set / Single Item

- Set

- Block Only

-

Preload(N・m)

- Clearance

- Clearance

-

Accuracy Standards(N・m)

- Standard Grade

-

Material

- Carbon Steel

- Stainless Steel

-

No. of Blocks(mm)

-

Lubrication Type

- Lithium Grease Filled

-

L Dimension Type

- Fixed Type

- Specified Type

-

Applicable Linear Guide

-

Rail Width WR(mm)

- 7

- 9

- 12

- 15

-

Block Material (Surface Treatment)

- Carbon Steel (Bearing Steel)

- Stainless Steel

-

Rail Material (Surface Treatment)

- Carbon Steel (Bearing Steel)

- Stainless Steel

-

Rail Surface Treatment

- Vacuum evaporated chrome plating

- none

-

type

- C-MLG

- C-MLGB

- E-GMLG

- E-SMLG

-

Lubrication Type(mm)

- Lubrication Applied

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 3 Day(s) or Less

- 10 Day(s) or Less

- 17 Day(s) or Less

- 18 Day(s) or Less

- 19 Day(s) or Less

- 20 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Can linear guides or sliders be purchased separately?

- Answer: Taking into account the accuracy of products, single slider models clearly indicated in the catalog can be purchased, and no others can be purchased.

- Question: Can the stainless steel guide rails be guaranteed not to rust?

- Answer: Stainless steel is a product that has a certain antirust function compared to carbon steel, but it cannot be guaranteed that it will never rust. Depending on the operating environment, there may also be short-term rust.

- Question: What problems should be paid attention to when the linear guide is installed vertically?

- Answer: Attention should be paid to prevent the slider from falling off and causing the balls to fall off during installation.

- Question: What does micro preloading in linear guide mean?

- Answer: MISUMI's linear guides control the clearance by selecting the size of the internal ball. Through the negative clearance, the rigidity is improved and the elastic displacement is reduced. This is preloading. Generally speaking, the life and accuracy of the micro preloading type will be better than that of the standard clearance type.

- Question: Linear guide indicators include basic dynamic load rating and basic static load rating. Which indicator is the reference when selecting?

- Answer: The basic dynamic load rating is used to calculate the rail life, and the basic static load rating is used to calculate the maximum allowable load.

- Question: Can the corresponding linear guide products be selected according to the third-party guide rail model?

- Answer: MISUMI offers third-party brand replacement services, so as long as the third party product model is given, we can replace it with corresponding MISUMI model. For details, please contact the customer service email or call the customer service phone.

- Question: Can the rail or slider be repaired if it is damaged?

- Answer: Repair service is not provided, re-purchase is recommended.

- Question: Can linear guide length be arbitrarily specified?

- Answer: It can be specified arbitrarily. However, MISUMI linear guides are divided into length fixed type and length specified type, and in case of length specified type, the length dimensions for length fixed type cannot be specified.

Products like this...

| Part Number |

|---|

| C-MLG12-195 |

| C-MLG12-220 |

| C-MLG12-345 |

| E-SMLGB5 |

| E-SMLGB7 |

| E-SMLGB9 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Rail Length L | Block Type (mm) | Assembly Height H | Nominal Part Number | Rail Type | Set / Single Item | Preload (N・m) | Accuracy Standards (N・m) | Material | No. of Blocks (mm) | Lubrication Type (mm) | Lubrication Type | L Dimension Type | Applicable Linear Guide | Rail Width WR (mm) | Block Material (Surface Treatment) | Rail Material (Surface Treatment) | Rail Surface Treatment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

166,263 IDR | 1 Piece(s) | Available | Same day | - | 195 | [Standard] Standard Block | 13 | 12 | Standard Rail | Set | [Clearance] Normal Clearance | Standard Grade | Carbon Steel | - | Lubrication Applied | Lithium Grease Filled | Fixed Type | - | 12 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | none | |

175,500 IDR | 1 Piece(s) | Available | Same day | - | 220 | [Standard] Standard Block | 13 | 12 | Standard Rail | Set | [Clearance] Normal Clearance | Standard Grade | Carbon Steel | 1 | Lubrication Applied | Lithium Grease Filled | Fixed Type | - | 12 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | none | |

220,263 IDR | 1 Piece(s) | Available | Same day | 10 | 345 | [Standard] Standard Block | 13 | 12 | Standard Rail | Set | [Clearance] Normal Clearance | Standard Grade | Carbon Steel | - | Lubrication Applied | Lithium Grease Filled | Fixed Type | - | 12 | Carbon Steel (Bearing Steel) | Carbon Steel (Bearing Steel) | none | |

202,778 IDR | 1 Piece(s) | 17 Day(s) | - | - | - | - | - | - | - | - | - | - | - | Lubrication Applied | - | - | - | - | - | - | - | ||

117,205 IDR | 1 Piece(s) | 20 Day(s) | - | - | - | - | - | - | - | - | - | - | - | Lubrication Applied | - | - | - | - | - | - | - | ||

118,724 IDR | 1 Piece(s) | 20 Day(s) | - | - | - | - | - | - | - | - | - | - | - | Lubrication Applied | - | - | - | - | - | - | - |

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

How can we improve?Bagaimana Kami bisa meningkatkan Pelayanan?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Kebijakan Privacy

Thank you for your cooperation.Terima kasih atas kerjasama anda.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy Walaupun Kami tidak dapat langsung menjawab saran yang ditulis di lembar ini, informasinya akan kami review untuk peningkatan pelayanan dikemudian hari

Silahkan pergunakan Forms Permintaan.

Kebijakan Privacy